Better Touch Better Business

Contact Sales at UFO.

UFO Battery is a professional supplier of lithium-ion batteries and power solutions.

English

English

Introduction: It is understood that the New EU Battery Law to be implemented on January 1, 2022 requires that by 2030, the proportion of recycled materials used for cobalt, nickel and lithium in battery production shall not be less than 12%, 4% and 4%; By 2035, the regeneration of cobalt, nickel and lithium is understood to be required in the & quotation.

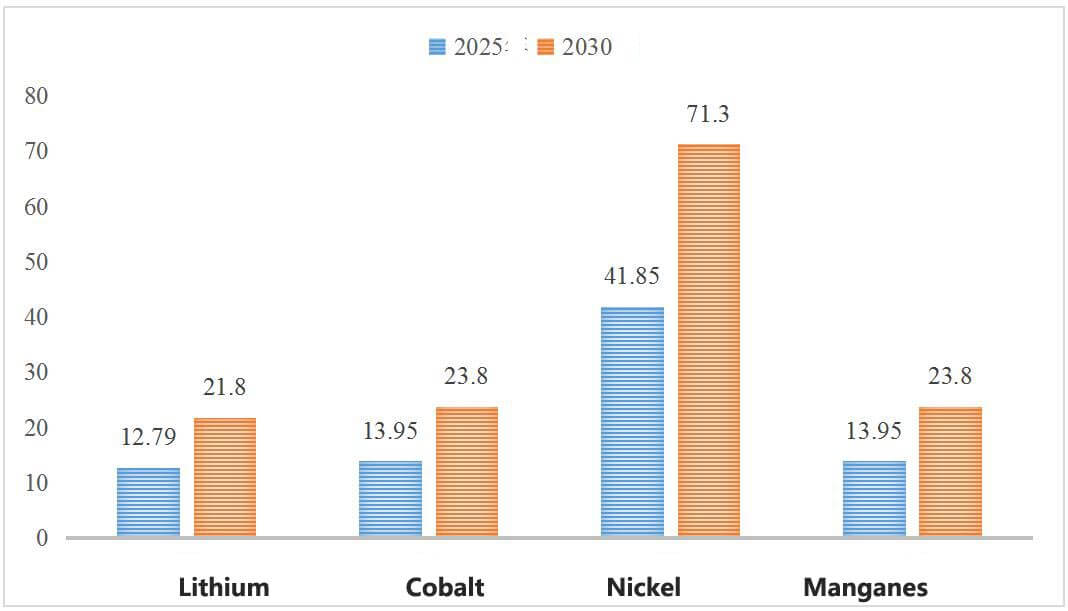

New EU Battery Law to be implemented on January 1, 2022: By 2030, the proportion of recycled materials used for cobalt, nickel and lithium in battery production shall not be less than 12%, 4% and 4%. By 2035, the proportion of recycled materials used for cobalt, nickel and lithium shall not be less than 20%, 12% and 10%. These requirements in the New Law; will pose new challenges to the global new energy vehicle industry. In the first 11 months of this year, the production of new energy vehicles has reached 3.023 million, an average year-on-year increase of 1.7 times, a penetration rate of 12.7%, a cumulative number of more than 7 million vehicles, and a supporting installead capacity of more than 428GWh. Sales are expected to reach 35 million vehicles by 2025, with demand for lithium, cobalt, nickel and manganese reaching 38,500 tons, 42,000 tons, 126,000 tons and 42,000 tons respectively. In Europe and the United States, especially Norway, the penetration rate of electric vehicles is close to 100%. According to authoritative data, global car sales will reach 93.9 million in 2025. According to the 24.8% market penetration rate, the demand for new energy vehicles will reach 23.25 million, and the annual battery demand will reach 1725GWh.

2025/2030 Global Demand for Lithium, Cobalt, Nickel and Manganese for New Energy Vehicles (10,000 tons) According to relevant statistics, it is estimated that after 2035, the lithium, cobalt and nickel resources available for exploitation can only support the current year’s demand for 35 years, 14 years and 36 years respectively. And with the implementation of the global electrification strategy, it may face a situation where there is no ore to mine. 2.jpg Years of exploitable global resources (years) Faced with such a severe situation of new energy resources, Chinese enterprises have already made arrangements in advance. In 2020, in order to promote the high-quality development of the new energy vehicle industry, the Ministry of Industry and Information Technology ;

New Energy Vehicle Waste Power Battery Comprehensive Utilization Industry Standard Conditions (2019 Edition) stipulates that the recovery rate of recycled lithium, nickel and cobalt shall not be lower than 85%, 98.5% and 98.5%. In 2020, the State Council&;s New Energy Vehicle Industry Development Plan (2021-2035);, by 2025, the sales volume of new energy vehicles will reach about 20% of the total sales volume of new vehicles, and it is proposed to promote the development of the entire value chain of power batteries and encourage enterprises to improve the guarantee capacity of key resources such as lithium, nickel and cobalt. In 2021, the Ministry of Finance, the State Administration of Taxation, the National Development and Reform Commission, the Ministry of Ecology and Environment and other four ministries and commissions issued the Comprehensive Utilization of Resources Enterprise Income Tax Preferential Catalog (2021 Edition), which proposed that the use of waste batteries to be recycled into products can obtain certain preferential tax policies.

The state has launched this series of industrial policies on new energy, which has a profound impact on the sustainable development of the new energy industry and provides a strong policy guarantee for the subsequent battery recycling. Founded in 2001, Grammy Co., Ltd. has long foreseen the embarrassment that the new energy industry will face. Professor Xu Kaihua, chairman of the board, first put forward the strategic concept of building a new energy life cycle value chain in 2015, and began to lay out the industrial chain of recycling new energy resources, and comprehensively promoted the construction of a green supply value chain of power battery recycling-nickel-cobalt lithium battery raw material recycling-battery material recycling-power battery recycling. 3.jpg Glimmer New Energy Life Cycle Value Chain Under the guidance of this strategic concept, Glimmer Company actively constructs a 2 + N +2 waste battery recycling system, in which 2 refers to the two major battery recycling and disposal centers of Glimmer Wuhan Park and Wuxi Park, as well as the two major resource utilization centers of Jingmen Park and Taixing Park, while refers to other recycling and disposal bases of Glimmer Tianjin and Shenzhen + other social recycling networks.

At present, in the system built by Glimmer, there are three companies that have announced the comprehensive utilization of new energy waste power batteries by the Ministry of Industry and Information Technology, and have been officially recommended by the Ministry of Industry and Information Technology as a typical case of comprehensive utilization of waste power batteries. As of today, Glimmer has designed a total dismantling capacity of 450,000 sets/year, recycled waste batteries (except lead-acid batteries) account for more than 10% of China&;s total scrap, recycled nickel resources account for more than 8% of China’s original nickel production, and recycled cobalt resources are 2.2 times of China’s original cobalt production. According to statistics, from 2010 to 2020, the United States will recycle 36,000 tons of recycled cobalt resources, equivalent to 13.36 million tons of original cobalt ore output. Ultrafine cobalt powder will occupy 50% of the global market. Recycled nickel resources are 30,000 tons and 1500 tons of lithium carbonate, equivalent to the output of 2 million tons of primary nickel ore and 15,000 tons of lithium ore.

Global layout of the new energy life cycle value chain construction.In 2021, Grammy took the lead in completing the construction of South Korea’s POSCO power battery recycling base, with an annual processing capacity of 20,000 tons, while actively laying out power battery recycling plants in Europe and Southeast Asia to build a global power battery recycling industry system. At the same time, the company and Toyota Motor, CATL, Samsung, ECOPRO, BYD, Yiwei Lithium Energy, Funeng Technology, Ruipu Energy and other 430 upstream and downstream to carry out battery material directional recycling, waste power battery recycling, the use of cooperation to promote the new energy vehicle industry to achieve from green to green.

Glimmer South Korea POSCO Power Battery Recycling and Processing Base It is estimated that by 2025, the total recovery of the company’s power batteries will exceed 250,000 tons, and the recovery of scarce resources such as cobalt, nickel and lithium will reach 3-50,000 tons, with a comprehensive utilization value of about 10 billion tons. In 2018, Grammy Co., Ltd. won the runner-up title of Global Circular Economy Multinational Corporation Award and is the only circular economy enterprise in China to receive this honor. In 2020, Glimmer’s Innovative Model of Urban Waste Battery Recycling project successfully won the 2020 Paulson Sustainable Development Award-Green Innovation Category award, marking that Glimmer’s power battery recycling technology has been recognized by the world. Through the recycling of used power batteries, the problem of resource depletion can be effectively solved.

Forecast of global demand for lithium, cobalt, nickel and manganese resources recovered from power batteries

In the near future, the European Union will also launch a draft Green Economic Recovery Plan to encourage European car companies to sell clean energy vehicles and establish a new procurement mechanism for clean energy vehicles. According to the global sales forecast and analysis of new energy vehicles, the global cumulative decommissioned power batteries will reach 2.81 million tons (about 327GWh) in 2025, while the renewable lithium, cobalt, nickel and manganese resources through the recovery of global power batteries will account for about 28%, 28%, 23% and 42% of the current year’s demand respectively. In 2030, the global cumulative decommissioned power batteries will reach 20.29 million tons (about 2123GWh), the amount of lithium, cobalt, nickel and manganese renewable through the recovery of global power batteries accounted for 107%, 107%, 89% and 161% of the current year’s demand, respectively. 6.jpg Forecast of global demand for lithium, cobalt, nickel and manganese resources recovered from power batteries With the further improvement of the penetration rate of new energy vehicles, the amount of metal resources recovered from batteries will effectively guarantee the metal demand of new energy vehicles. Through the recycling of waste batteries, it not only improves the self-sufficiency rate of raw materials, reduces upstream dependence, builds a closed-loop operation mode of each link, realizes resource recycling, and effectively alleviates the shortage of valuable metal resources such as nickel, cobalt, and lithium. An important way to respond to the requirements of the New EU Battery Law.

ABOUT US

CONTACT US

Copyright © 2019 SHENZHEN UFO POWER TECHNOLOGY CO., LTD. | Privacy Policy | All Rights Reserved

mike@ufo-battery.com

mike@ufo-battery.com